Mode of operation

The probe, a tube covered with a silicone diaphragm, is placed inside the exhaust gas pipe of the fermenter. Pressure adjusted instrument air is conducted through the probe and enriched with ethanol diffusing through the diaphragm.

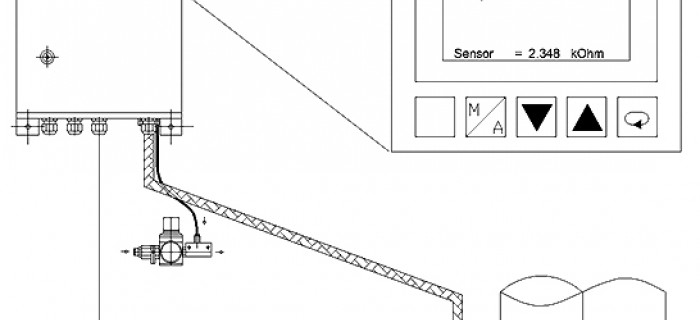

For gas analysis a semiconductor sensor element is used, which is located in the switchboard and connected with the ethanol enriched air stream. Depending on the transmitted signal, the corresponding ethanol concentration in the fermentation mash is calculated. Signal linearization is carried out by use of pre-installed calibration data.

Process values such as the calculated ethanol concentration, temperature and sensor resistance are shown on the LCD display of the switchboard. For the purpose of process control, the linearized signal is converted to a standard current signal and two limit relay contacts which can be used as input signal for any process control system or for visualization and/or documentation.