Top product quality and low energy demand

Vogelbusch offers highly specialized custom solutions that optimize process economics for compliance with precise specifications for product quality and available steam pressures.

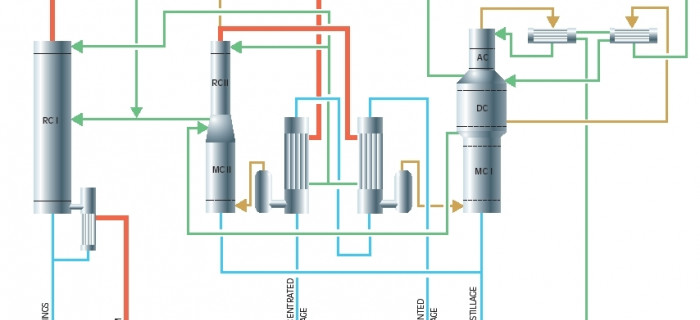

Raw alcohol is distilled from the fermentation mash and through further separation steps rectified and concentrated. The careful design of the distillation and rectification ensures not only the desired product quality, but brings the energy consumption of the MultiPressure system down to

- 1,950 kg per 1,000 liters of neutral alcohol

- 1,050 kg per 1,000 liters of bioethanol

By thermal integration with other process units, the plant’s ground-breaking energy-saving properties are boosted further still.