Rectification units for premium alcohol quality

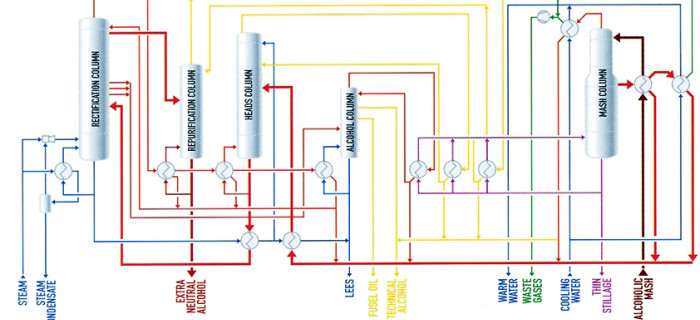

Rectification is used in alcohol production for the purification of raw alcohol obtained from mash distillation.

With a carefully considered selection of process parameter it plays the key role in tailoring the alcohol quality as required for neutral and extra neutral alcohol (ENA).