Maturing, fining, filtration

PRODUCT ISOLATION AND CONCENTRATION

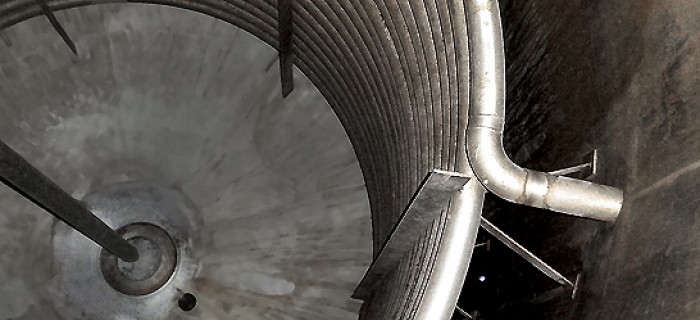

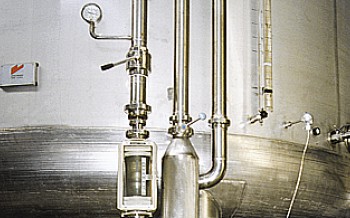

The fresh (raw) vinegar discharged from the fermenter is allowed to mature in the ejection tanks for several weeks. In the course of maturing impurities which cause turbidity (such as bacteria, coagulated proteins, precipitated salts) settle to the bottom of the tanks.

If required, the clarifying of the raw vinegar can be advanced with fining agents in specially equipped fining tanks. To remove any remaining solids, the mature vinegar passes through a filter module. Before bottling or bulk filling, it is finally filtered over a de-germination filter and diluted to the desired concentration with process water.