Sporebox for spore propagation

For the production of spores, in particular filamentous micro-organisms, Vogelbusch has developed a patented propagation system.

For the production of spores, in particular filamentous micro-organisms, Vogelbusch has developed a patented propagation system.

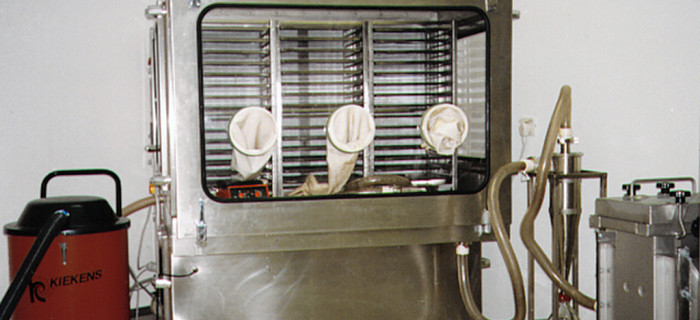

The Sporebox consists of two parts, a supply unit, and a sterile compartment for spore production.

The supply unit contains all necessary equipment to ensure optimal cultivation conditions, such control of humidity, temperature, pressure and airflow rate as well as measuring instruments, recorder, ventilator and a compressor.

The production compartment has windows for optical inspection of the growth of the micro-organisms. Integrated gloves are used for all manipulations from the outside. Sterile ventilation is carried out by airflow through HEPA filter.

The production compartment is equipped with 60 plates, each with a utilizable area of 1,260 cm², resulting in a total surface of 7.56 m².

For priming a blend of agar, molasses and mineral salts is sterilized and applied on the plates. Once the substrate is solidified, the surface is inoculated with the micro-organism.

After a cultivation period under controlled conditions, the spores are cautiously dried, harvested and bottled. The bottled spores can be stored in a customary deep freezer at -20 °C for extended periods.

The advantages of spore propagation in a Vogelbusch Sporebox are

Depending on the substrate (molasses) quality, for instance 0.8 – 1.4 kg spores of Aspergillus niger can be grown in each production cycle. The production cycle for Aspergillus niger lasts about 14 days: 5 days for cultivation, 5 days of drying, 4 days for harvesting, cleaning and preparations for the next cycle.

All in all some 25 kg of Aspergillus niger can be produced in one Sporebox per year.

A basic unit consists of agar preparation, a Sporebox and the harvesting apparatus. Production capacity is extended with additional Sporeboxes while using the existing set of preparation and harvesting equipment.

The harvesting apparatus comprising a separator (cyclone), a vacuum cleaner, a safety filter for exhaust air and appropriate connections is included in delivery.

The agar preparation vessel (60 liters) can be supplied optionally.

SPOREBOX |

|

| Net weight | 770 kg |

| Dimensions | 2200 x 1370 x 1790 mm |

| Power supply | 240 V / 400 V |

| Cold water supply, outlet | DN 20 |

| Drain (sewer) | DN 50 |

HARVESTING APPARATUS |

|

| Power supply | 400 V |

AGAR PREPARATION VESSEL |

|

| Power supply | 240 V |

| Compressed air | Pressure cyclinder |

The Sporebox has to be placed in an air-conditioned room with a temperature of 30 °C ± 1 °C at all points. A minimum of eight air exchanges per hour and the installation of coarse and fine filters in the ventilation ducts are recommended.

The air outlets should be mounted flush in the ceiling, just as the lighting fixtures. Ceiling, walls and floor should be as smooth as possible, fillets are recommended. The room should be without windows.

The Alcohol School

05/12/2025

April 06 - 11, 2025 | Vienna, Austria