Thermally integrated designs - 54

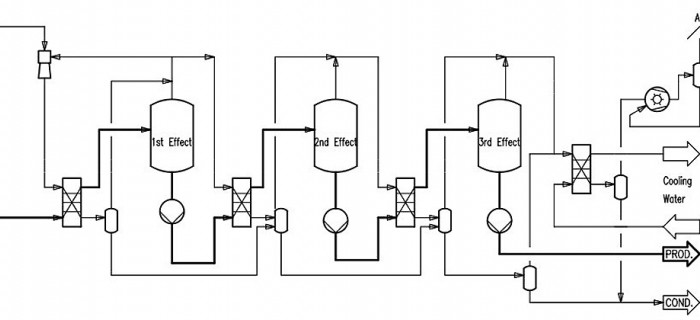

Aiming at lowest possible energy demand, our design considerations also cover the thermal integration of the evaporator within the complete production facility by reusing waste heat from other process groups.

A standard solution in Vogelbusch alcohol plants is the reuse of drier vapors for heating the multi-effect stillage evaporator. By this design the demand of life steam for the evaporator can be reduced to zero.

Alternatively the coupling of distillation / rectification with the evaporator also leads to a significant reduction of steam demand for the concentration of stillage or vinasses.

Also flash vapors as always available in sweetener or alcohol plants are a valuable source for heating product or effluent evaporators.

More about » Thermal integration with distillation units