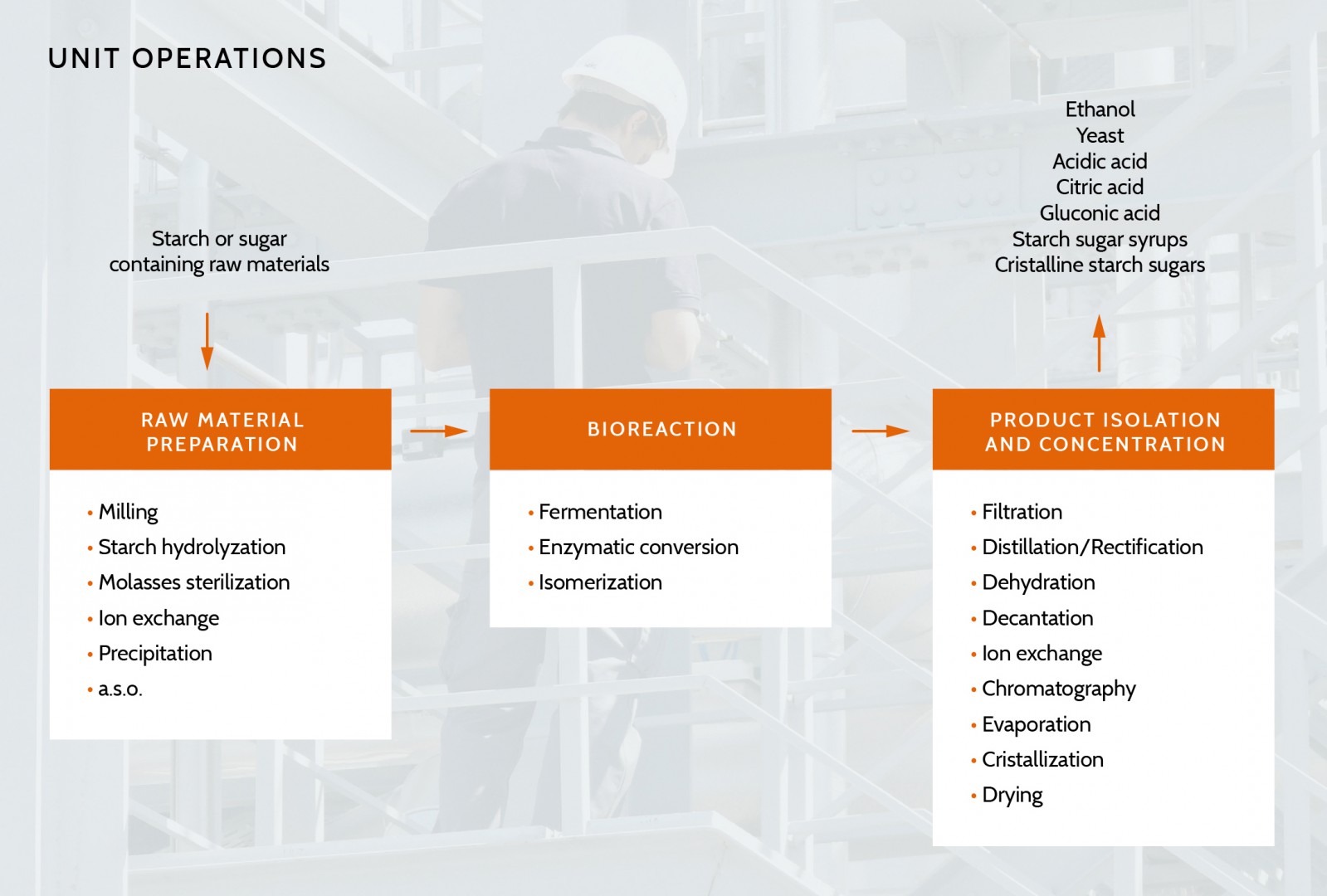

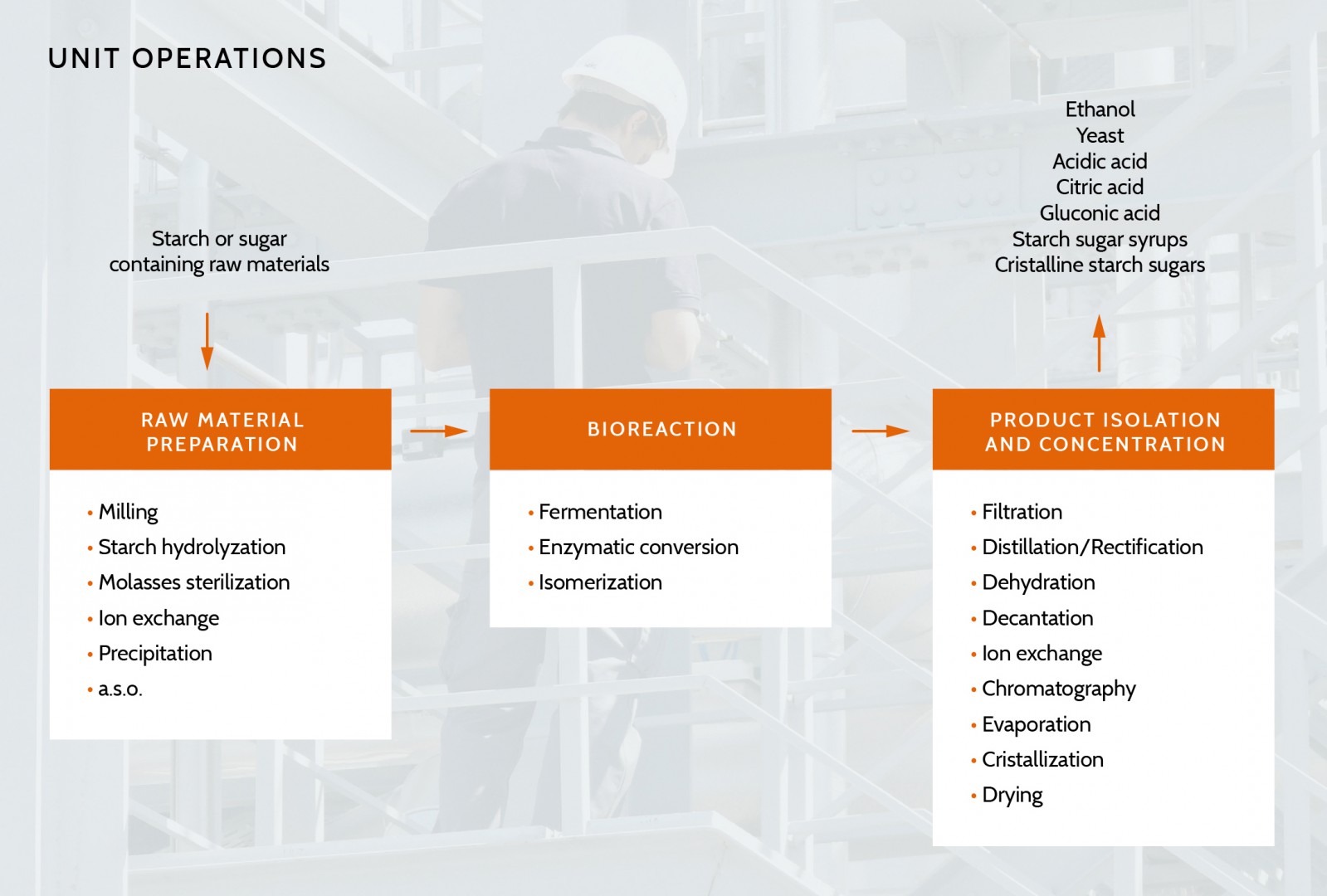

Every step matters

From the raw material to the end product, Vogelbusch has unique expertise in the implementation of biological production techniques and related upstream and downstream processes.

From the raw material to the end product, Vogelbusch has unique expertise in the implementation of biological production techniques and related upstream and downstream processes.

Along with the design of complete plants we also supply single processing units and integrate them into your manufacturing facility.

Contact us for advice and support with

Starch and sugar containing natural sources require different strategies and processes for biotech applications. We provide an array of pretreatment processes, which are tailored to the composition of the substrate and its specific requirements of fermentation processes and enzymatic conversions.

Our technologies can utilize a wide range of biobased feedstocks, including sugars derived from cellulose conversion.

Grain crops such as maize, wheat, triticale, sorghum (milo), or tubers such as cassava, sweet potatoes or potatoes

»Sugar beet, sugar cane or sweet sorghum in the form of molasses, thick juice or syrups

»Determination of suitability of input materials for bioprocess needs is carried out in our laboratories

»Hydrolysis is a break down of a chemical bond by addition of water. The reaction is catalyzed either by acids or, more common in the biobased industries for their beneficial process properties, by enzymes.

In bioprocess applications, hydrolyzation is used to break the molecular structure of polymers such as starch, cellulose, or inulin, into smaller fractions of polysaccharides (= polymers of sugar molecules) and ultimately to glucose or fructose.

Vogelbusch applies two-step enzymatic conversion processes (liquefaction and saccharification) that are adjusted to either

Fermentation is the conversion of pre-treated raw material to desired products by using the metabolic activities of application-specific micro-organisms.

Vogelbusch has developed own processes using fungi, bacteria and yeasts, and has the know-how to ensure robust production and system integrity in batch, fed batch and continuous fermentation processes. With our many years of experience with microbial production techniques we can come up with the ideal configuration for every fermentation system and we know how to maintain optimal conditions for microorganism and substrate.

Vogelbusch MultiCont© process for highly reliable continuous alcohol fermentation.

»Testing feedstocks and micro-organisms for suitability in industrial fermentation.

»Isomerization is a chemical process of transformation of a molecule into its isomeric form. The new molecule has the same chemical composition but the atoms are arranged in a different way, resulting in different physical and chemical properties.

Isomerization is applied by Vogelbusch for the conversion of glucose into fructose to increase the sweetness of the product. The resulting isoglucose syrup is further processed to commercial high fructose syrups.

The process is designed using immobilized enzymes in a set of parallel operated fixed bed reactors. In consideration of the aging of the enzymes, process parameters (flow, temperature) are adjusted for each reactor to ensure stable syrup properties at a constant feed rate to the system. Maximizing productivity and lifetime of the enzymes is achieved by appropriate treatment of the feed stream.

Distillation and rectification are the standard procedure for separating mixtures of liquids with different boiling points by intensive mass transfer between liquid and vapor phase. A typical example of distillation is the separation of fermented mash into raw alcohol and stillage. Rectification is used for concentration and purification of the alcohol.

Vogelbusch has unique experience with all distillation and rectification needs in the ethanol industry. With our advanced column systems we have set the industry standard for premium product quality and energy saving processes.

Our proprietary designs are the solid foundation to develop and install the optimum solution for every customer, from standard configurations to completely customized systems.

Our generally recognized, highly efficient energy recovery and re-use system.

»Advanced thermal integration techniques considerably reduce your process energy demand.

»Rectification units for highest purity and organoleptic quality standards.

»Dehydration is used to eliminate water from ethanol or other chemicals for product purification. Required for bioethanol production and other industrial applications, the final water content can be reduced as low as 0.01 % vol,. Systems in industrial use include adsorption with molecular sieves, entrainer dehydration and membranes.

By merging specialized process know-how with existing technology Vogelbusch succeeded in pioneering the use of pressure-swing adsorption (PSA) technology for ethanol dehydration which has become state-of-the-art. The Vogelbusch process employs a two-bed system using molecular sieves. It is reliable and easy to operate and particularly suitable for heat integration with other units.

Pressure swing adsorption with synthetic molecular sieves for alcohol dehydration.

»Centrifugation is a method for separating mixtures of solid and / or liquid components by using rotating equipment with high g-forces such as decanters, centrifuges and separators.

Vogelbusch evaluates and specifies the separation requirements considering the feed and product properties and incorporates the suitable rotating equipment from trusted producers into its processes.

In alcohol production decantation is an approved measure to remove suspended solids from stillage and for the recovery of corn oil. In starch sweetener processing it is applied for demudding of raw glucose solution prior to filtration.

In combination with crystallization processes different types of batch and continuous centrifuges are deployed in citric acid and dextrose production.

Nozzle and disk separators are used in yeast manufacturing.

Evaporation is an approved solution in the bioprocess industry, not only for the concentration of intermediate and final products but also for the separation of thin slops or low concentrated waste water streams into a concentrated fraction and a condensate stream, which often are reused in the process.

Vogelbusch offers proprietary evaporation systems for many different applications such as the concentration of mono- and polysaccharides, polyols, citric acid, yeast cream and fruit juice as well as corn steep water, distillation stillage, effluents, slops and other chemical and foodstuff industry products.

A wide range of proprietary evaporator designs and energy saving concepts is available to meet the most diversified requirements associated with bioprocesses

Multiple use of primary heat input and thermal integration of evaporation plants

»Ion exchange is a separation process for the removal of dissolved impurities by using gel type or macroporous resins. Typically strong acidic cation exchange and weak or strong basic anion exchange resins are used.

In bioprocessing it is employed upstream to treat raw materials for biological processing requirements, and downstream to purify and de-colorize the final product to comply with commercial specifications.

Vogelbusch know-how covers the embedding of ion exchange into the overall process in fixed bed reactors with co- or counter-current regeneration, including the selection of cation and anion exchange resins and automation for continuous operation. Eco-friendly design of regeneration procedures minimizes fresh water and chemical consumption and product losses.

Chromatography is a versatile method for separating components of a solution on basis of the different bonding properties of molecules. The technique is state-of-the-art for analysis and processing in the food industry and for innovative pharma and biotech applications.

Batch type chromatography is mostly used for analysis and in pharmaceutical plants. In the commodity business, the continuously working simulated moving bed (SMB) chromatography is preferred. It is a separation technique that emulates the countercurrent flow of the solid phase and liquids and hence has a lower demand of eluent and a better utilization of the adsorbent.

Vogelbusch developed a novel SMB chromatography carried out in a single column. This technology forms a perfect solution for pilot scale and small production capacities as often seen in the area of fine chemicals and other special applications.

For processing of large quantities like in the production of high fructose syrups or in the production of organic acids commercial scale chromatographic systems are embedded in our process solutions.

Simulated moving bed technology in a single adsorbent bed

»Filtration is a mechanical procedure for the separation of solid substances from liquids by using appropriate types of porous material as filter. Bioprocess applications include the separation of microorganisms, the concentration of biomass and the clarification of an intermediate or the final product.

Depending on the application, filtration requirements can vary widely. We select suitable methods from first class manufacturers in line with process conditions and product specifications.

A wide variety of proven filtration systems is utilized, including

Further, dead-end cartridge filters are used for sterilization of fermentation air, fermentation substrates and clean steam. Similar filters are used for final filtration of product solutions to comply with microbiological specifications.

Crystallization refers to the separation of a substance or compound from a concentrated solution in the form of crystalline structures.

Particular emphasis in this process is placed on the isolation of pure solid substances. Target can be the formulation of a final product which is subsequently dried, or the purification of an intermediate which in turn is dissolved and processed further.

In the production of citric acid crystallization is used to isolate the product as calcium salt from the fermentation broth. Citric acid as well as starch sugars are crystallized to formulate the final product.

Vogelbusch crystallization designs include cooling as well as evaporation crystallizers. Sophisticated crystallizing and separation technology ensures the desired product quality.

A multitude of drier technologies is applied in the bioprocess industries to achieve the required final product quality. Methods differ in

In common use are spray and fluidized bed driers, ring and rotary drum driers as well as tube bundle driers.

We determine the drying requirements depending on the product and integrate the suitable drier technology in line with available energy sources. Particular attention has the reuse and recycling of heat within the overall plant so to reduce the primary energy demand, for instance by using the thermal discharge from drying to run an evaporation.