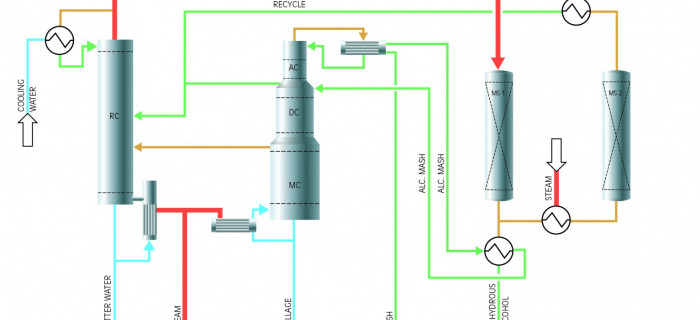

Thermally integrated designs

Heat recovery from thermal processes and reuse of secondary energy within and across process units allow a more effective use of primary energy. Besides resource conservation, successful solutions consider the investment costs and the available infrastructure too.

Process optimization of this sort cuts operating costs and improves the greenhouse gas performance of the plant.