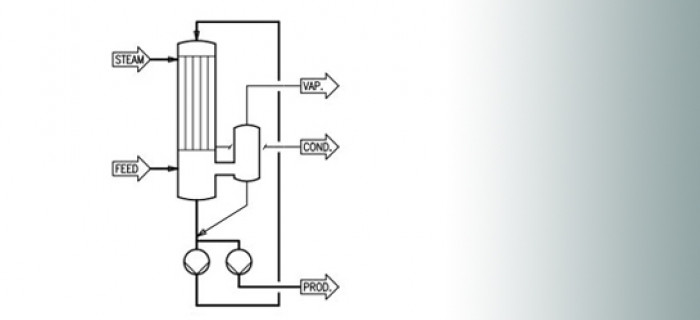

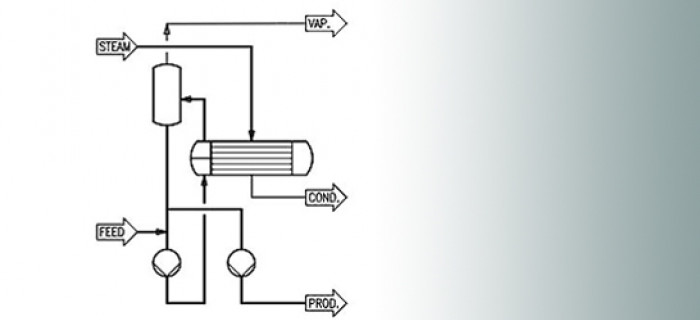

Varied Design Concepts for Evaporation

Varied in line with each application, our design concepts take into account the product characteristics, cleaning concepts, the required capacity, availability and pressure of steam and cooling water as well as local energy costs.

Since concentration and hence the properties of the evaporated solution change considerably during the process, a well-chosen combination of different evaporation modes in one unit ensures high efficiency.