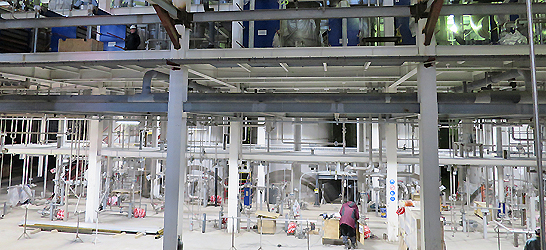

Our expectations have been totally satisfied. It's been three years working at full capacity and we are very pleased with the work done on this plant.

Lic. Adrián Urquía, Promaiz S. A., Bioethanol Plant, Alejandro Roca, Cordoba, Argentina

Lic. Adrián Urquía, Promaiz S. A., Bioethanol Plant, Alejandro Roca, Cordoba, Argentina

We were served by a great team and we are very pleased how the business was treated.

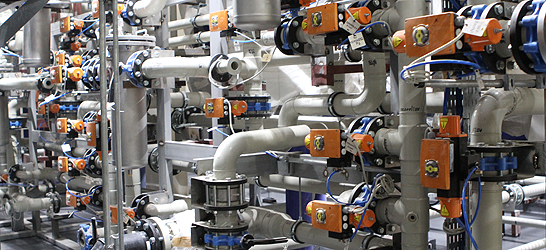

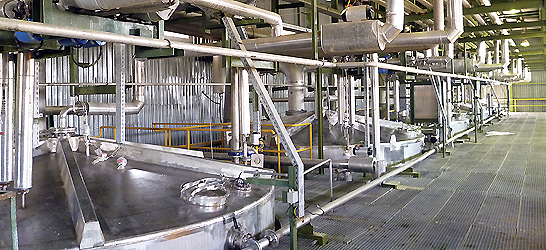

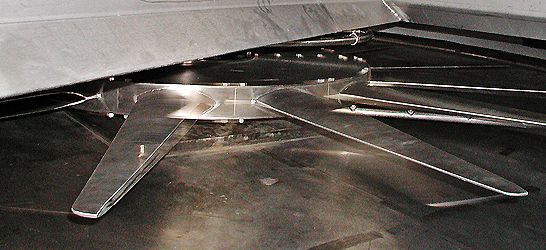

In particular and most important we want to transmit our satisfaction with the efficiency of the vinegar fermenter.

Alexandra Almeída, Mendes Gonçalves, Vinegar Fermenter, Golegã, Portugal

In particular and most important we want to transmit our satisfaction with the efficiency of the vinegar fermenter.

Alexandra Almeída, Mendes Gonçalves, Vinegar Fermenter, Golegã, Portugal

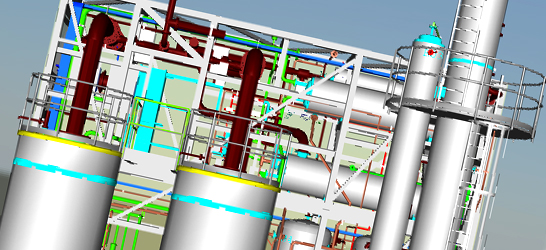

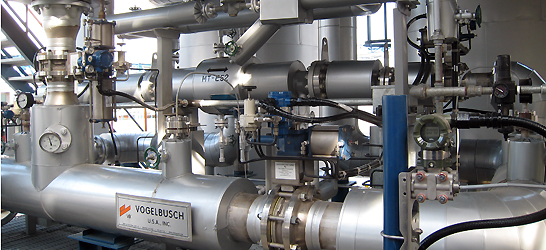

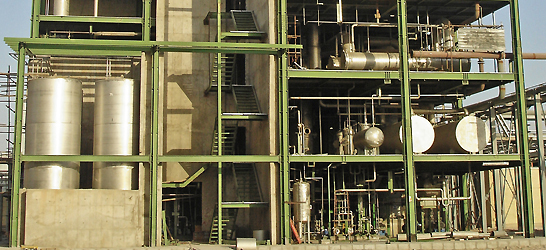

Based on the reconstruction according to the consulting by Vogelbusch, the rectification plant now shows fully satisfactory fine alcohol quality yield and performance.

Dr. Wilkening, KWST, Rectification Unit, Hannover, Germany

Dr. Wilkening, KWST, Rectification Unit, Hannover, Germany

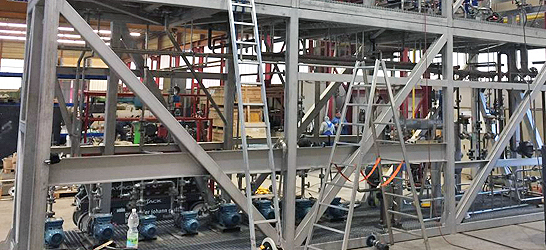

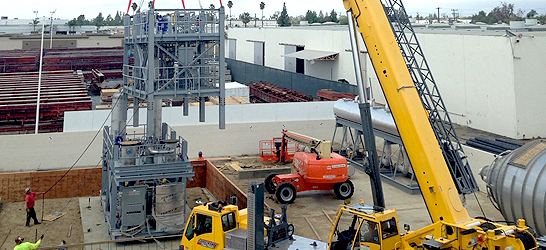

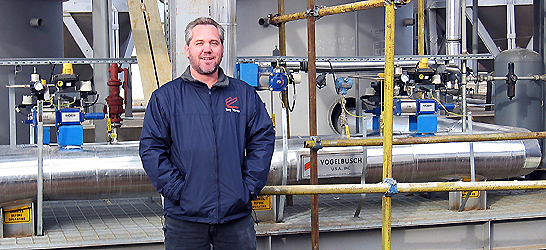

We chose Vogelbusch’s distillation and dehydration systems for their proven capabilities, which are vital as we commercialize our advanced bioenergy technology.

Mark Niederschulte, INEOS Bio JV Bioenergy Center, 2G Bioethanol Plant, Vero Beach, Florida

Mark Niederschulte, INEOS Bio JV Bioenergy Center, 2G Bioethanol Plant, Vero Beach, Florida

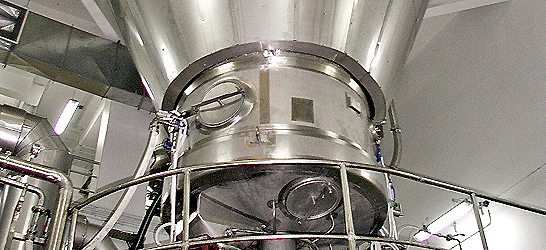

The plant, which was commissioned in the spring of 2005, is outstanding thanks to its efficient continuous fermentation method coupled with an integrated, optimized energy concept.

Press Release 1.9.2006, Südzucker AG, Bioethanol Plant, Zeitz, Germany

Press Release 1.9.2006, Südzucker AG, Bioethanol Plant, Zeitz, Germany

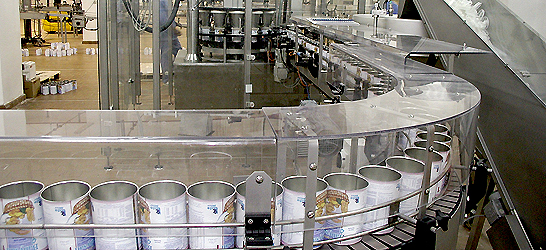

The addition of ethanol will allow our Cedar Rapids plant to increase production and improve asset utilization, while providing us with new flexibility to maximize returns from multiple market opportunities.

Tom Malkoski, Penford Products, Bioethanol Plant, Cedar Rapids, Iowa, United States

Tom Malkoski, Penford Products, Bioethanol Plant, Cedar Rapids, Iowa, United States

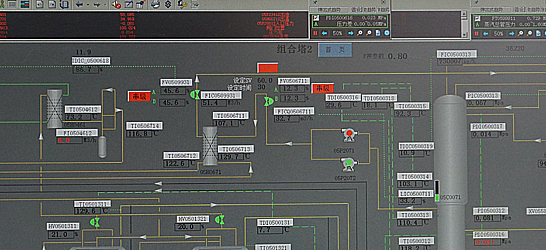

After close cooperation in a friendly atmosphere the start-up of the plant was performed successfully. It is in operation since 10 months now and we are fully satisfied with the very competitive final alcohol quality and performance from this well equipped production line.

Wang Chang Nan, Harbin Winery Factory, Neutral Alcohol Plant, Harbin, China

Wang Chang Nan, Harbin Winery Factory, Neutral Alcohol Plant, Harbin, China

We opted for Vogelbusch because we were aiming to produce top quality potable alcohol.

It was also important to us to build the plant as quickly as possible.

Yulian Belev, Almagest AG, Neutral Alcohol Plant, Verinsko, Bulgaria

It was also important to us to build the plant as quickly as possible.

Yulian Belev, Almagest AG, Neutral Alcohol Plant, Verinsko, Bulgaria