Technology for Vinegar Production

The acetic acid in vinegar acts as a natural preservative and it is a condiment commonly used in the food processing industry just as in household applications. Vinegar refines salad dressings and pickled vegetable and is also traditionally in use for medical and cleaning purposes.

On this page you can find out how vinegar is produced and how Vogelbusch can contribute to setting up a vinegar plant.

How is vinegar made?

For biological production of vinegar, acetic acid bacteria's ability to convert ethanol into acetic acid is utilized. The bacteria are added to wine, fermented fruit juices or diluted alcohol and supplied with oxygen. The formation of acetic acid from ethanol is associated with heat development. After a maturing period the vinegar is clarified in a fining and filtration process.

Vinegar know-how and technology

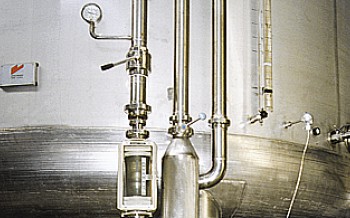

The Vogelbusch vinegar process employs submerged fermentation in which vinegar bacteria homogeneously scatter in the fermenting mash and no carrier material is used. Air supply is carried out with a well-conceived rotating aeration system. Its design addresses particular bioengineering issues such as oxygen transfer, mash circulation, cooling requirements and foam formation.

Just as you wish, our design packages and equipment can cover either only the key components (fermenter along with aerator and the process control system) or the complete process line, including measuring & control and laboratory equipment.

Your benefits at a glance

- Exceptionally efficient aeration system: energy saving, high yield and consistent product quality

- Gentle, economical cooling system

- Low labor requirements with fully automated fermentation

- High flexibility in terms of raw materials and product specifications

- Integration potential with alcohol plant

Product types

Vinegar types differ depending on their source of raw material