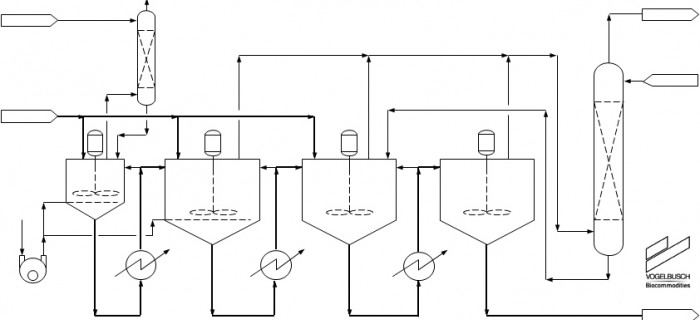

Vogelbusch MultiCont© continuous alcohol fermentation system

Vogelbusch’s continuous fermentation is highly reliable and achieves high alcohol concentrations and excellent yields continuously over extended periods of time.

The MultiCont© process was introduced to the alcohol industry back in 1970 with resounding success. The process has since been refined, and it is now considered the state-of-the-art technology for alcohol and bioethanol fermentation.